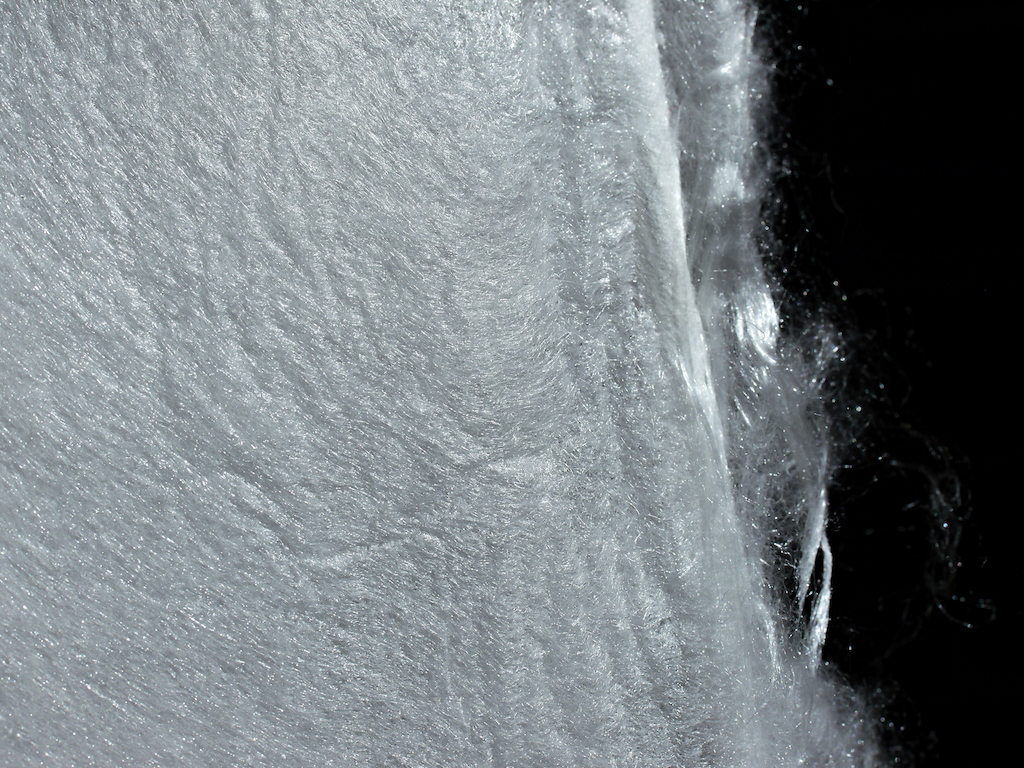

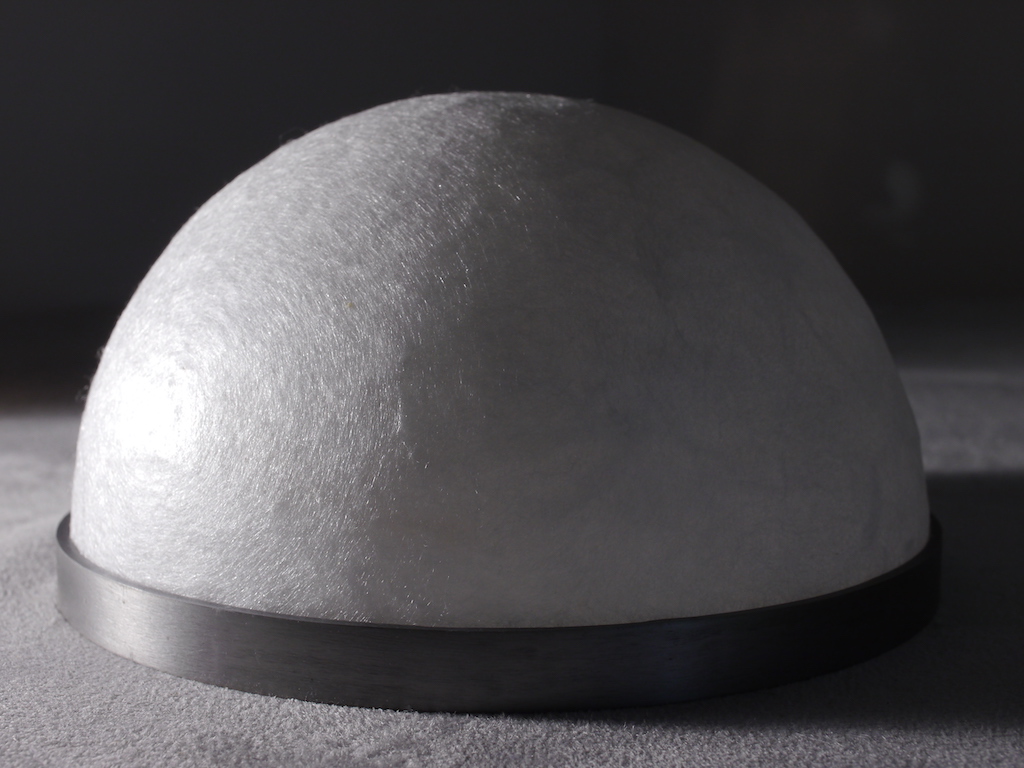

Flat-spun mulberry silk is a mesmerizing and ingeniously aesthetic wonder of Nature that appears like pure Zen: bright and clear.

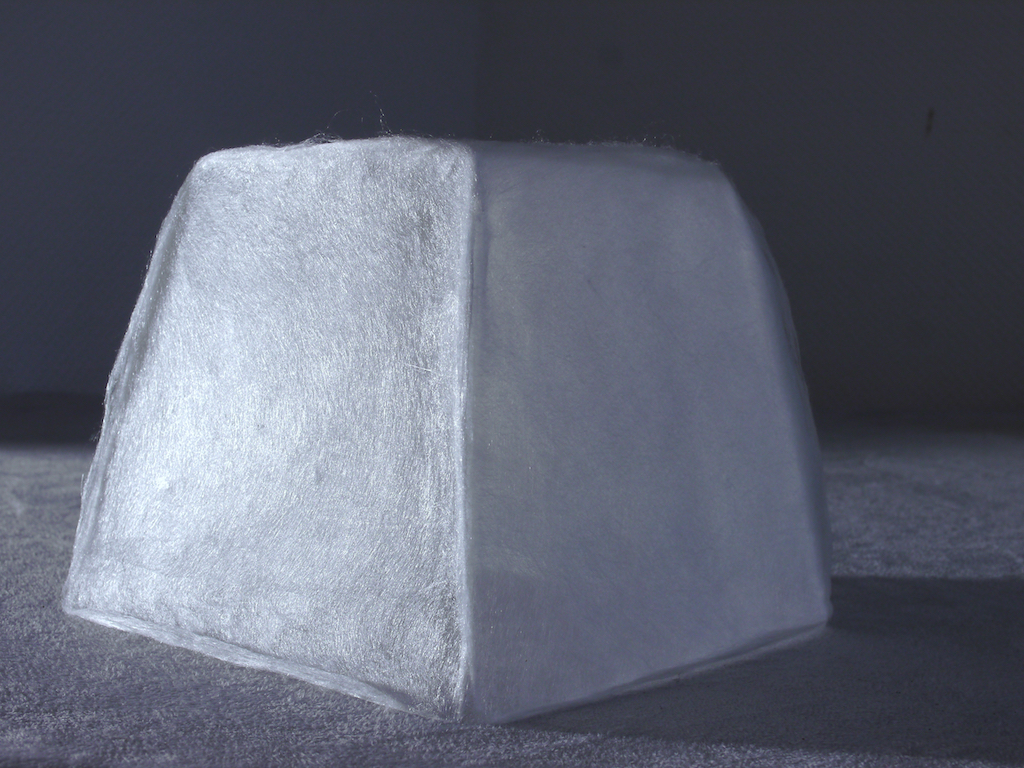

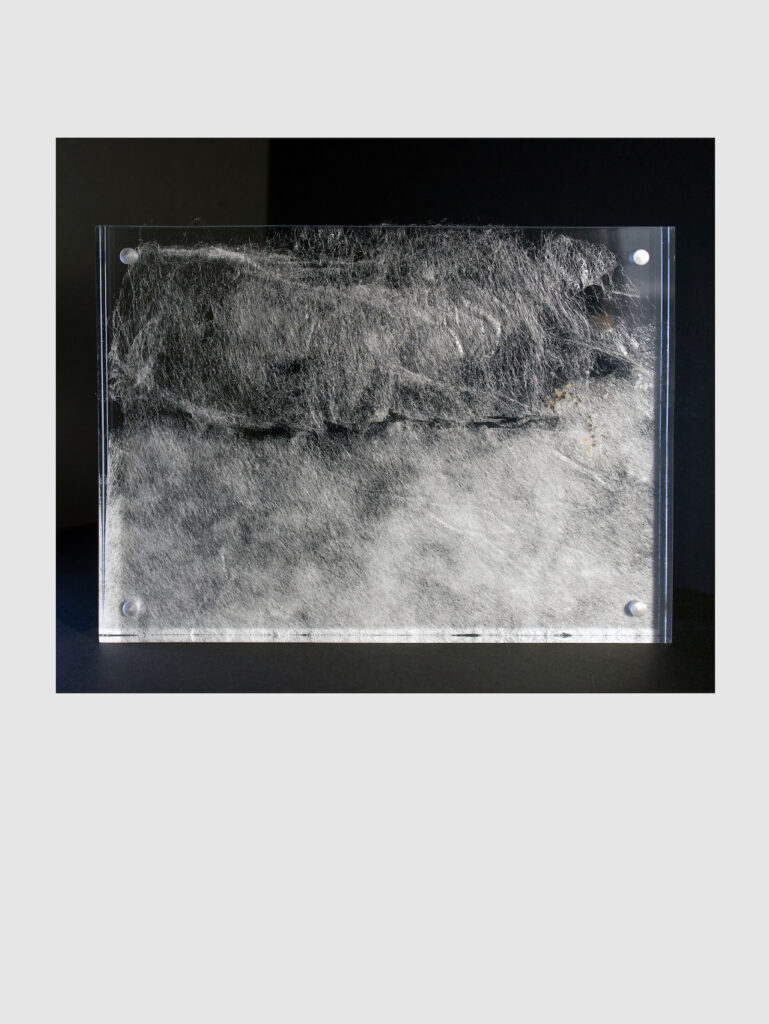

Mulberry silk is sought after as the world’s most noble, sophisticated and highest quality silk, famous for its unparalleled brilliance. No other silk appears as lustrous. The mulberry silk thread is of a triangular shape. Hence, when the light hits the silk, it bounces back. With its translucency, it is the perfect material for the creation of light objects. Lit from behind, the transparency is visible; lit from the front, its gleaming appearance is enchanting.